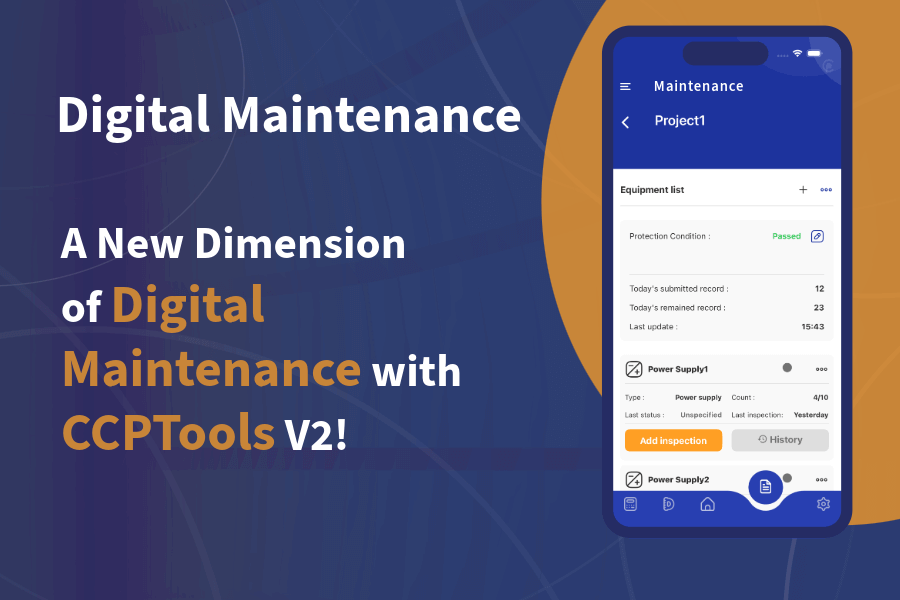

We are pleased to introduce what is arguably the most significant enhancement to CCPTools V2; The new Maintenance section has been created to enable faster and more organised cathodic protection activities in the field.

This includes a set of digital maintenance forms tailored for:

- Power Supply Units

- Anode Groundbeds

- Test Points

- Junction Boxes

Maintenance Features

The new maintenance feature allows users to define different equipment and customise each form for each part. For example, for each junction box, users can specify the number of terminals, the presence and value of the shunt and resistor, and their separate labels. During inspections, users can enter measurements and the general condition of the box based on the defined forms.

For test points, users can specify the application of the terminal – whether it is connected to the structure, a polarisation coupon or a permanent reference electrode. They can also record all measurements (e.g. ON, OFF potential) for that test point, along with its general condition and notes.

For power supplies (e.g. transformer rectifiers), users can define the TR control mode and the number of terminals. They can assign the terminals to positive, negative, reference electrode, earth or data connections.

For anode groundbeds, users can enter both condition and potential measurements, either as a single unit or separately for each anodes.

For all four types of equipment, users can define the units of measurement. When the data is exported to Excel, the application will unify all measurements in the selected units.

This customised approach ensures that each piece of equipment has its own form. It also helps users stay organised and accurate during inspections and maintenance.

You can use the new maintenance section for both sacrificial and impressed current cathodic protection systems, providing a consistent and clear user experience designed for the rigours of real field work.

Exporting Maintenance Data

Users can also export maintenance data to Excel files for record keeping, analysis or sharing. The exported files are fully mobile and desktop PC compatible, giving you unprecedented flexibility throughout your workflow.

CCPTools reduces paperwork and maximises efficiency by digitising maintenance tasks and ensuring that key information is always at your fingertips – anytime, anywhere – helping to maintain high levels of data accuracy.

And more …

We can provide customised digital maintenance forms for cathodic protection, corrosion surveys and technical inspections based on your specific needs. Not only will these forms keep your data secure and easily accessible, they’ll also reduce human error in inspection and maintenance. For feedback or enquiries, please contact us at info@ccptools.com.

We invite you to explore the Maintenance section of CCPTools V2, now available on both iOS and Android.

The CCPTools Team 🌐 www.ccptools.com